https://kwiktech.com.au/wp-content/uploads/2023/04/Compression.png

726

786

info@kwiktech.com.au info@kwiktech.com.au

https://kwiktech.com.au/wp-content/uploads/2022/02/logo-med.png

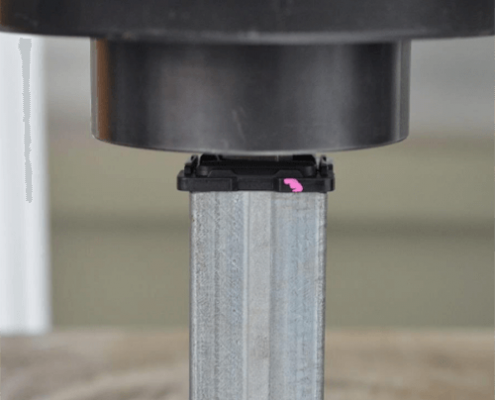

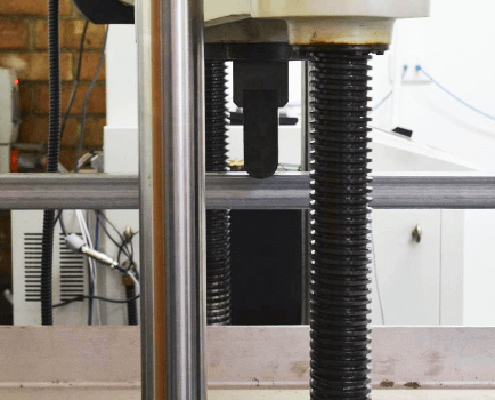

info@kwiktech.com.au info@kwiktech.com.au2023-04-28 08:02:082023-04-28 08:27:30Compression Load Testing – Galvanized Beams to Kwiktech Brackets

https://kwiktech.com.au/wp-content/uploads/2023/04/Compression.png

726

786

info@kwiktech.com.au info@kwiktech.com.au

https://kwiktech.com.au/wp-content/uploads/2022/02/logo-med.png

info@kwiktech.com.au info@kwiktech.com.au2023-04-28 08:02:082023-04-28 08:27:30Compression Load Testing – Galvanized Beams to Kwiktech Brackets

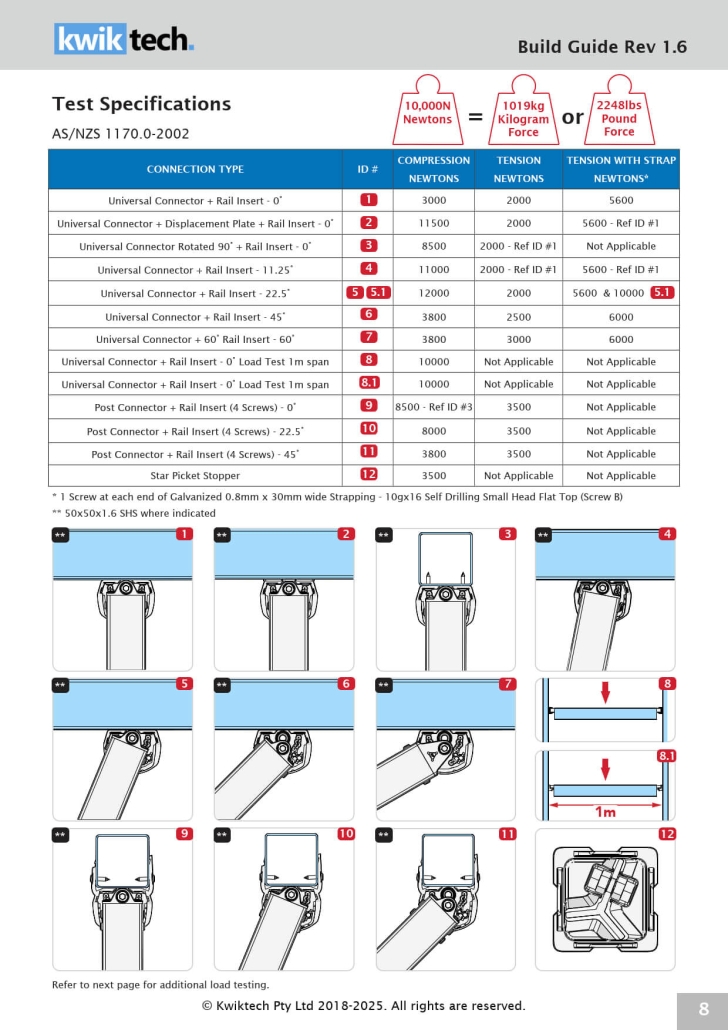

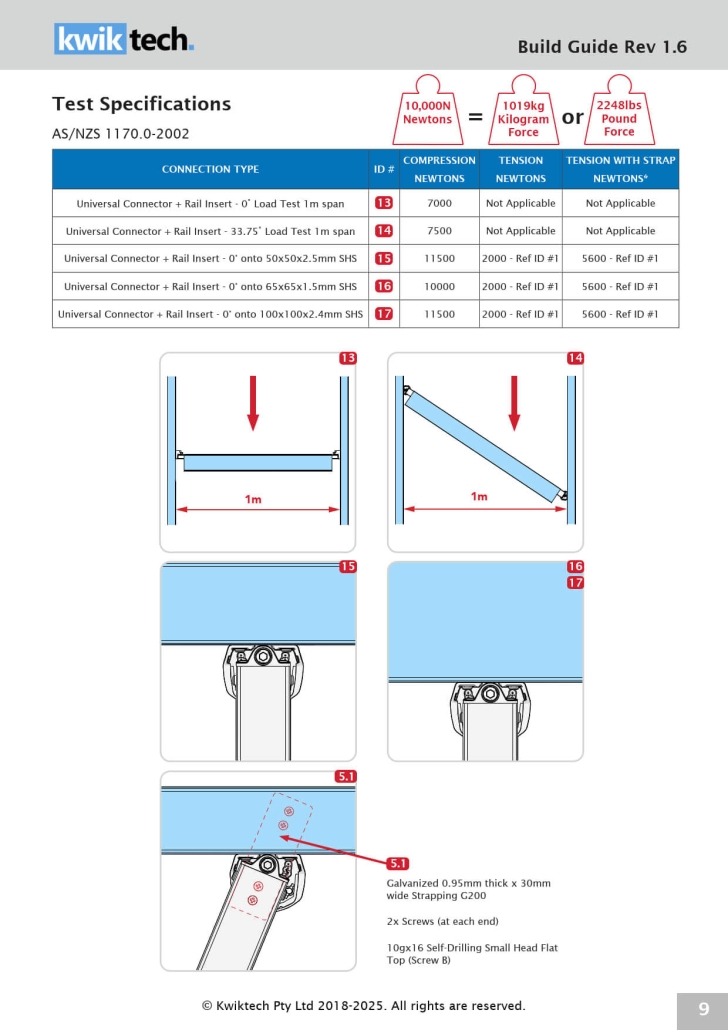

Universal Connector

Rail Insert

60° Rail Insert

FACT

Nylon 6 is a type of engineering thermoplastic that is known for its strength, toughness, and resistance to wear and impact.

Nylon 6 is a popular choice for applications that require high strength and durability, such as in the construction, automotive, and aerospace industries. The addition of 30% glass fiber further enhances the strength and stiffness of the material, while the UV additive helps to protect it from degradation due to exposure to sunlight.

Using Nylon 6 with glass fiber and UV additive is a smart choice for Kwiktech connectors, as it provides a high level of durability and resistance to the elements, while still being lightweight and easy to install. This material is also non-conductive, which may be beneficial in some applications.

Overall, Kwiktech connectors are made from a high-quality, engineered material that is well-suited for metal joining applications. The use of Nylon 6 with glass fiber and UV additive ensures that these connectors will be strong, stable, and durable over the long term, making them a good choice for both DIY enthusiasts and professionals in the construction and engineering industries.

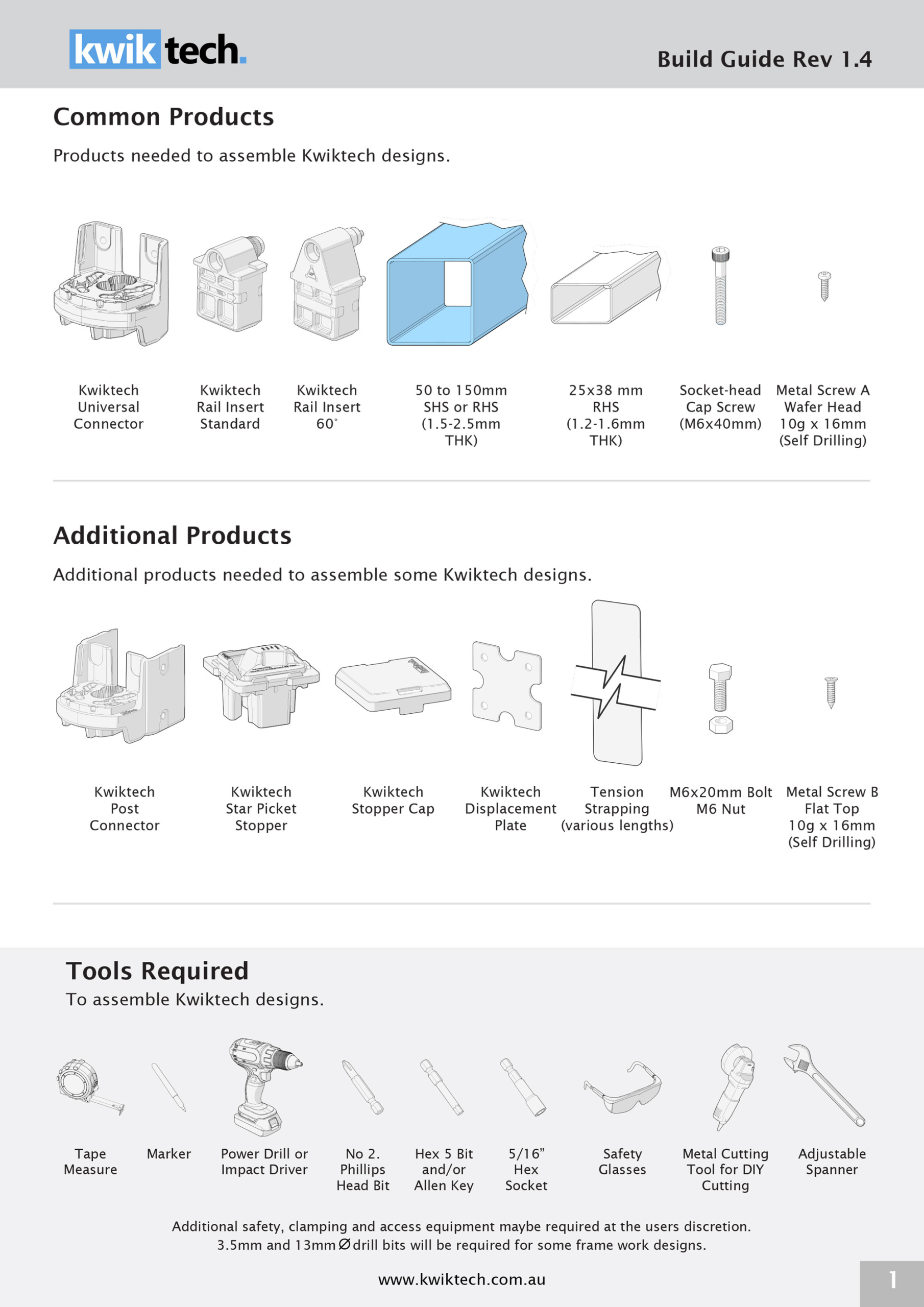

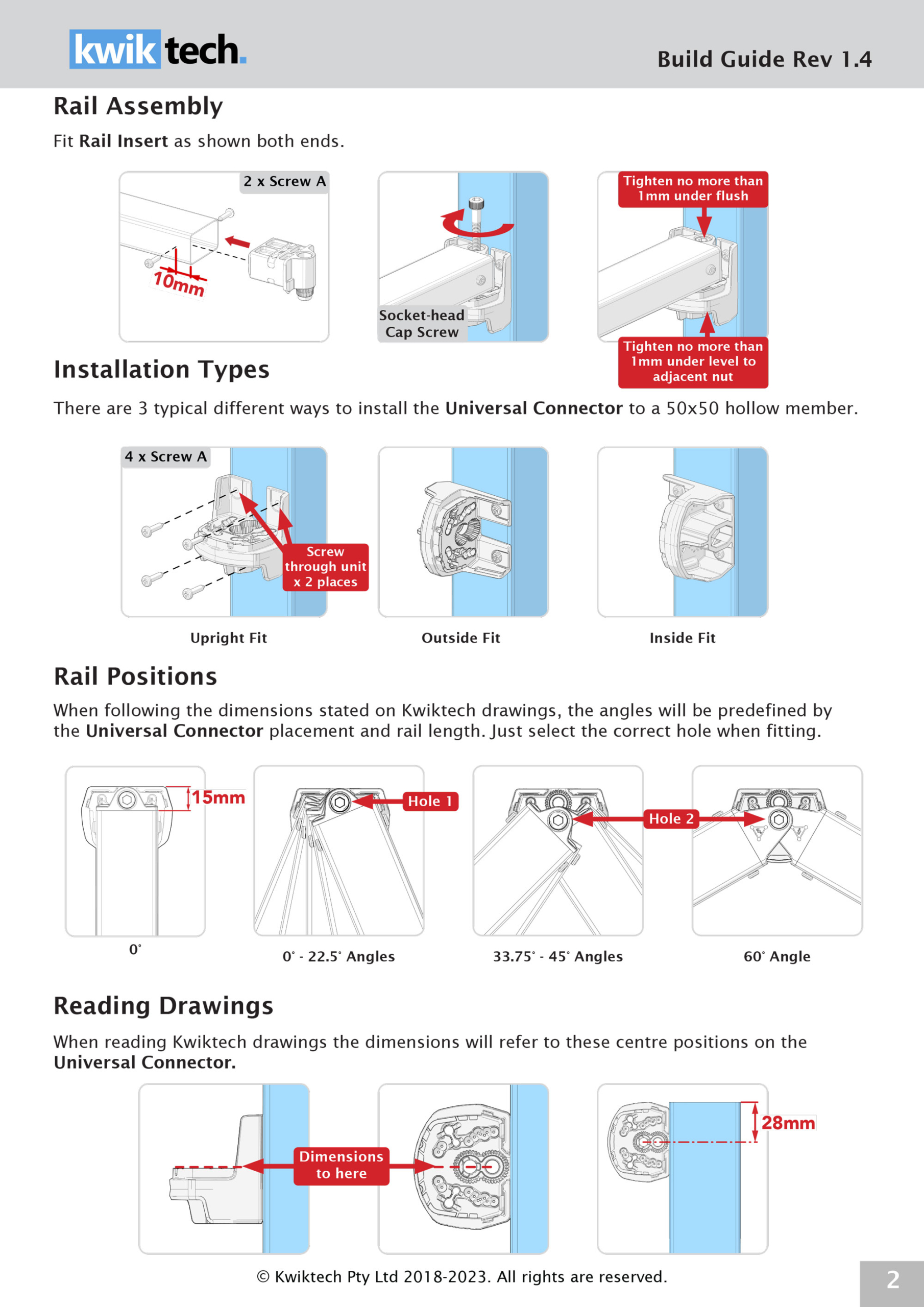

Load and Compression Testing conducted by international heavyweights Intertek gives you complete confidence when designing and building with Kwiktech. See our NATA-accredited reports tested to AS/NZS1170.0 HERE

Specially formulated Nylon 6 Thermoplastic provides Ultra Violet Protection by dispersing UV Light to well below impact-full limits to protect against fading and cracking. It ensures optimum mechanical stiffness for years to come, with all Kwiktech Connectors coming with a 10 Year UV Guarantee.

Thanks to Kwiktech’s ingenious design and clinical precision it is a case of simple mathematics ensuring your hollow metal framework builds perfectly square every time. Kwiktech’s available Locking Angles guarantee precision to ensure as long as your Connectors are positioned correctly, your framework will build perfectly square, every time.

Nylon 6 Polyamide Resin is the world’s most performance-proven Engineering Plastic thanks to its excellent fatigue properties while providing high impact and mechanical strength. Additional Glass Reinforcement of 30% adds additional strength, stiffness, toughness, dimensional stability and wear resistance for the ultimate Connection.

Kwiktech enables even the most inexperienced DIY’er to fabricate a lightweight hollow metal framework using only standard power tools already found in most sheds – Tape Measure, Standard Impact Driver (or Power Dill), No 2 Phillips Head Drive Bit and a Hex 5 Impact Drive Bit. Take DIY Fabrication to the next level and use an Angle Grinder with Cut-Off Wheel to cut your lengths of hollow metal.

Available Locking Angles of 0°, 11.25°, 22.5°, 33.75°, 45° and 60° and included Angles of 56.25°, 78.75°, 90° and 120°. Fabricate with complete freedom and effortlessly secure your locking angle with a single M6 Socket Head Cap Screw and assemble and disassemble your framework as many times as you like.

Internal testing confirms fabricating with Kwiktech is up to 3x faster than welding, with absolutely no preparation, clean up or expensive equipment required. Simply fix your Connectors directly onto your hollow metal and let the Connectors do all the work – no welding, cutting angles, grinding, painting or spending countless hours getting everything square.

Kwiktech not only ensures your framework is perfectly square, but also perfectly flush making your framework ideal for cladding on both sides. All Connectors sit with millimetre precision inside the framework to ensure no protrusions, making your framework ideal for Gates, Privacy Screens, Steel Framed Sheds and much, much more.

With no calculations, expensive equipment or cutting angles required, Kwiktech opens up DIY fabrication to the masses with the world’s easiest, quickest and cheapest DIY fabrication system ever. As long as you can use a tape measure and standard impact driver (or power drill), you can now fabricate a perfectly square hollow metal framework with ease.

Kwiktech Easy DIY Build Manuals enable you to effortlessly find your required hollow metal cut lengths and connector positions no matter what framework you decide to fabricate.

Kwiktech is Australian Made for Australian Conditions, and nothing states this more than its working temperature range. Able to withstand freezing temperatures of -30°C and extreme heat of 90°C before even the slightest sign of changes in mechanical properties to ensure no matter where you live, Kwiktech will perform in even the harshest of Australian conditions.

Kwiktech is proudly 100% Australian Made and Owned from 100% Australian-sourced materials. Capitalising on Adelaide’s long history as a world leader in Injection Moulding for the automotive industry. Kwiktech has been tested and developed alongside industry leaders to ensure the highest quality DIY fabrication system possible.

Tests

https://kwiktech.com.au/wp-content/uploads/2023/04/Compression.png

726

786

info@kwiktech.com.au info@kwiktech.com.au

https://kwiktech.com.au/wp-content/uploads/2022/02/logo-med.png

info@kwiktech.com.au info@kwiktech.com.au2023-04-28 08:02:082023-04-28 08:27:30Compression Load Testing – Galvanized Beams to Kwiktech Brackets

https://kwiktech.com.au/wp-content/uploads/2023/04/Compression.png

726

786

info@kwiktech.com.au info@kwiktech.com.au

https://kwiktech.com.au/wp-content/uploads/2022/02/logo-med.png

info@kwiktech.com.au info@kwiktech.com.au2023-04-28 08:02:082023-04-28 08:27:30Compression Load Testing – Galvanized Beams to Kwiktech Brackets https://kwiktech.com.au/wp-content/uploads/2022/03/Figure-1.jpeg

469

702

info@kwiktech.com.au info@kwiktech.com.au

https://kwiktech.com.au/wp-content/uploads/2022/02/logo-med.png

info@kwiktech.com.au info@kwiktech.com.au2022-03-16 23:06:282022-05-05 21:05:05Load Testing – Universal Connector

https://kwiktech.com.au/wp-content/uploads/2022/03/Figure-1.jpeg

469

702

info@kwiktech.com.au info@kwiktech.com.au

https://kwiktech.com.au/wp-content/uploads/2022/02/logo-med.png

info@kwiktech.com.au info@kwiktech.com.au2022-03-16 23:06:282022-05-05 21:05:05Load Testing – Universal Connector https://kwiktech.com.au/wp-content/uploads/2022/03/6b-t-495x400-1.png

400

495

info@kwiktech.com.au info@kwiktech.com.au

https://kwiktech.com.au/wp-content/uploads/2022/02/logo-med.png

info@kwiktech.com.au info@kwiktech.com.au2022-03-03 21:00:012025-07-17 08:53:35Tension Load Testing – Universal Connector

https://kwiktech.com.au/wp-content/uploads/2022/03/6b-t-495x400-1.png

400

495

info@kwiktech.com.au info@kwiktech.com.au

https://kwiktech.com.au/wp-content/uploads/2022/02/logo-med.png

info@kwiktech.com.au info@kwiktech.com.au2022-03-03 21:00:012025-07-17 08:53:35Tension Load Testing – Universal Connector https://kwiktech.com.au/wp-content/uploads/2022/03/7-2-t-495x400-1.png

400

495

John Watson

https://kwiktech.com.au/wp-content/uploads/2022/02/logo-med.png

John Watson2022-03-02 22:00:402025-05-23 17:43:46Compression Load Testing – Universal Connector

https://kwiktech.com.au/wp-content/uploads/2022/03/7-2-t-495x400-1.png

400

495

John Watson

https://kwiktech.com.au/wp-content/uploads/2022/02/logo-med.png

John Watson2022-03-02 22:00:402025-05-23 17:43:46Compression Load Testing – Universal Connector https://kwiktech.com.au/wp-content/uploads/2020/08/10b-t.png

594

500

John Watson

https://kwiktech.com.au/wp-content/uploads/2022/02/logo-med.png

John Watson2020-08-12 09:58:052022-03-17 10:11:40Compression Load Testing – Post Connector

https://kwiktech.com.au/wp-content/uploads/2020/08/10b-t.png

594

500

John Watson

https://kwiktech.com.au/wp-content/uploads/2022/02/logo-med.png

John Watson2020-08-12 09:58:052022-03-17 10:11:40Compression Load Testing – Post Connector https://kwiktech.com.au/wp-content/uploads/2020/08/11b-t.png

422

500

John Watson

https://kwiktech.com.au/wp-content/uploads/2022/02/logo-med.png

John Watson2020-08-12 09:48:402022-03-17 10:12:01Compression Load Testing – Star Picket Stopper

https://kwiktech.com.au/wp-content/uploads/2020/08/11b-t.png

422

500

John Watson

https://kwiktech.com.au/wp-content/uploads/2022/02/logo-med.png

John Watson2020-08-12 09:48:402022-03-17 10:12:01Compression Load Testing – Star Picket Stopper https://kwiktech.com.au/wp-content/uploads/2020/08/9b-t.png

431

500

John Watson

https://kwiktech.com.au/wp-content/uploads/2022/02/logo-med.png

John Watson2020-08-12 09:45:572025-07-17 08:56:51Tension Load Testing – Post Connector

https://kwiktech.com.au/wp-content/uploads/2020/08/9b-t.png

431

500

John Watson

https://kwiktech.com.au/wp-content/uploads/2022/02/logo-med.png

John Watson2020-08-12 09:45:572025-07-17 08:56:51Tension Load Testing – Post Connector https://kwiktech.com.au/wp-content/uploads/2022/03/8-t-495x400-1.png

400

495

John Watson

https://kwiktech.com.au/wp-content/uploads/2022/02/logo-med.png

John Watson2020-06-23 15:43:052022-03-17 11:03:33Post Connector and Hollow Metal Load Testing to Failure Point

https://kwiktech.com.au/wp-content/uploads/2022/03/8-t-495x400-1.png

400

495

John Watson

https://kwiktech.com.au/wp-content/uploads/2022/02/logo-med.png

John Watson2020-06-23 15:43:052022-03-17 11:03:33Post Connector and Hollow Metal Load Testing to Failure Point https://kwiktech.com.au/wp-content/uploads/2022/03/swim-t-495x400-1.png

400

495

info@kwiktech.com.au info@kwiktech.com.au

https://kwiktech.com.au/wp-content/uploads/2022/02/logo-med.png

info@kwiktech.com.au info@kwiktech.com.au2020-06-23 08:43:232025-05-12 13:44:28Strength Testing – Pool Barrier Components

https://kwiktech.com.au/wp-content/uploads/2022/03/swim-t-495x400-1.png

400

495

info@kwiktech.com.au info@kwiktech.com.au

https://kwiktech.com.au/wp-content/uploads/2022/02/logo-med.png

info@kwiktech.com.au info@kwiktech.com.au2020-06-23 08:43:232025-05-12 13:44:28Strength Testing – Pool Barrier ComponentsAll sales enquiries

Custom Design

Kwiktech improves on the centuries old technique of Compression & Tension Forces, as used in trusses for house construction, and catapults it into the 21st century thanks to state-of-the-art technology and cutting-edge manufacturing processes.